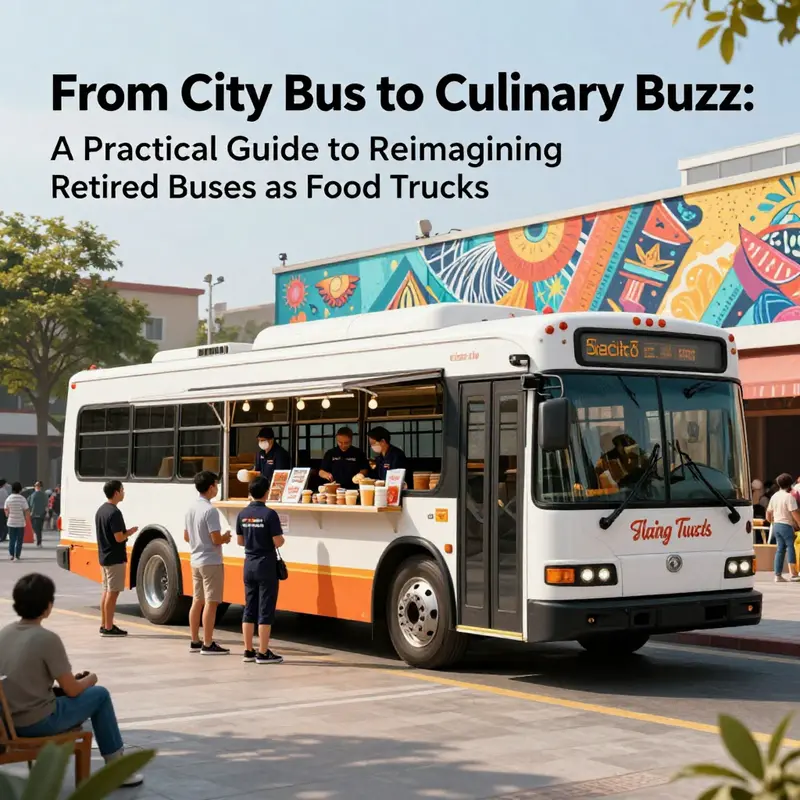

Picture a retired city bus rolling into your event space, not for transport but as a sparkling, offbeat dining destination. Turning a bus into a food truck blends design craft, safety discipline, and community spirit into a portable culinary stage. Whether you’re coordinating a festival, planning a campus pop-up, or nurturing a neighborhood market, this approach offers a sustainable, memorable centerpiece that travels with your audience. This guide breaks the journey into four concrete chapters that build on one another: assessing the vehicle and its purpose, navigating legal and regulatory requirements, detailing the essential modifications and equipment, and shaping design, branding, and day-to-day operations. Expect practical checklists, real-world examples from cities that already embraced mobile canteens, and actionable tips you can adapt to your city’s rules and your event timelines. By the end, you’ll see how a bus can become a flexible, community-driven dining hub that suits budgets, schedules, and the spirit of your audience.

From Steel to Sizzle: Assessing the Bus and Defining the Mission Before You Convert a City Vehicle into a Food Truck

A city bus is more than a shell of steel and glass. It is a potential kitchen on wheels, a small theater for service, and a visible statement about how a city repurposes its assets. The decisive first move in converting a bus into a food truck is not choosing a recipe or the exterior color. It is a rigorous assessment of two intertwined questions: what the bus is capable of delivering in real-world use, and what condition and infrastructure must be in place to support that delivery. This twofold inquiry—the vehicle’s physical health and the project’s purpose—sets the tone for every subsequent decision, from layout and equipment to power sources and licensing. It also anchors the project in practical feasibility, ensuring that ambition does not outpace safety, regulation, or day-to-day reliability.

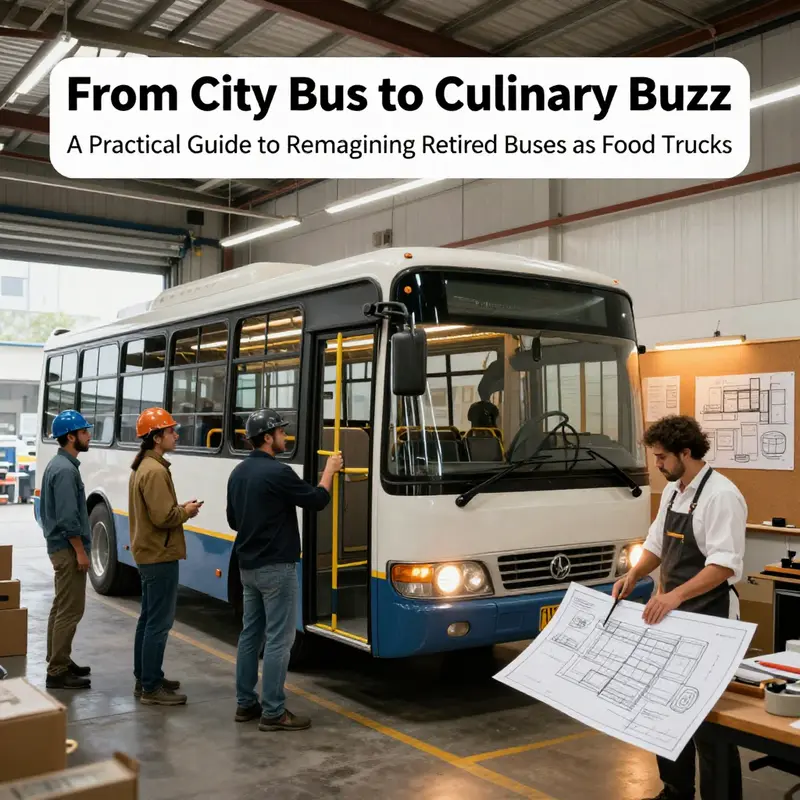

Begin with a clear-eyed look at the vehicle’s structural health and age. Retired public transport assets often carry a story in their frame: miles on the odometer, wear on the chassis, and the cumulative impacts of road use. An older bus may still have a sound steel skeleton, but it could also display corrosion in floor beams, weakened undercarriage mounts, or compromised roof integrity after years of exposure to weather. The assessment must go beyond cosmetic concerns. The objective is to determine whether the core chassis and body remain capable of safely supporting a commercial kitchen, heavy equipment, and frequent access to customers. In many urban conversion narratives, the chassis remains viable even after its passenger service ends, provided that critical structural elements are intact and the necessary reinforcements are carefully scoped and executed by qualified professionals.

The age and condition of the engine and drivetrain are equally relevant, even for a project that is primarily powered by alternative electrical systems. A bus whose propulsion—whether diesel, natural gas, or hybrid—shows signs of unreliability can become a liability once converted into a food operation. In practice, a thorough mechanical inspection is as essential as a visual survey of doors, stairs, and seating removal. An unreliable powertrain can jeopardize service plans, especially for a mobile unit expected to respond to peak demand in neighborhoods, transit hubs, or event venues. The goal is not to chase a pristine, showroom-like specimen but to identify a bus whose mechanical core can be stabilized, refurbished, or modernized within a sensible budget and timeline. When a bus passes that initial hurdle, the project can shift toward evaluating how its design influences the intended dining experience.

Next comes the definition of the primary purpose. The mission of the converted bus will dictate every subsequent modification. If the idea is a mobile dining experience aimed at serving meals to a specific community, the interior must accommodate kitchen equipment, refrigeration, water handling, and a comfortable customer interface while preserving enough space for safe circulation. This path resembles the Hui Min Canteen concept found in some northern regions, where buses are adapted to provide meals to residents with accessibility and reliability as core priorities. The layout emphasis in such scenarios is to create a practical workflow: a straightforward sequence from order to food preparation to service, with clear separation between raw areas and finished products. In contrast, a bus designed for quick, efficient service during commutes leans toward an open counter, compact cooking stations, and self-service interfaces that enable customers to grab meals on the go. Shenzhen’s bus-to-go model exemplifies this approach, prioritizing speed, visibility, and an intuitive customer path. For a more immersive or premium experience, a bus can be redesigned into a themed space, where branding, ambiance, and specialized preparation zones align with a distinctive concept—an approach seen in experimental projects that blend hospitality with mobility. The core takeaway is simple: the intended service model determines the scale and configuration of equipment, the placement of windows and service counters, and the flow of staff and customers. A bus that plans to park near a transit hub or park-and-ride lot may favor a compact yet highly efficient footprint, while a bus that aims to roam between neighborhoods and events might justify larger cold storage and a more flexible interior that can adapt to varying menus and hours.

Defining the purpose also clarifies regulatory considerations from the outset. The health and safety rules that govern a mobile food operation hinge on the service model and the vehicle’s final usage. A plan centered on elderly outreach, for instance, must integrate accessible design features without compromising food safety or ventilation. A route-focused, fast-service concept must balance speed with safe handling of hot equipment and proper waste management. Early discussions with local authorities about expected standards for sanitation, ventilation, fire safety, and vehicle dimensions can prevent costly redesigns later. In many jurisdictions, modifications are subject to a formal approval process that protects both the operator and the public. Roadworthiness remains essential when the vehicle continues to share the street with other traffic. Any alteration that affects doors, windows, or emergency exits must comply with applicable road-safety regulations and receive proper authorization before operation. Consulting with a regulatory framework on food handling and vehicle modification is a prudent early step. For those seeking a structured starting point, resources such as official guidance on navigating food-truck industry regulations offer a practical road map for aligning design with law. Navigating food-truck industry regulations.

The power question sits squarely at the crossroads of practicality and sustainability. A traditional bus configuration is not designed to run a kitchen, so its power system must be adapted. For many projects, the preferred path is a hybrid approach that blends electrical power with a reliable source of back-up energy. A mobile unit benefits from generators or battery systems that deliver consistent power to refrigeration, cooking appliances, lights, and ventilation. In an urban context, where noise, emissions, and space are considerations, there is a growing interest in electric or hybrid configurations. An electric drivetrain aligns with tightening city environmental standards and smooths access to charging infrastructure near busy corridors and event spaces. A modern, electrified conception reduces exhaust, simplifies permitting in some districts, and supports a quieter operation for street-based venues. The assessment phase should therefore include a high-level feasibility of power options, estimating energy requirements for typical service windows, peak loads for cooking equipment, and the practicality of charging during downtime between events or shifts. The end result of this stage is a clear preference for a power strategy that matches the service model, budget, and regulatory expectations rather than chasing a trend.

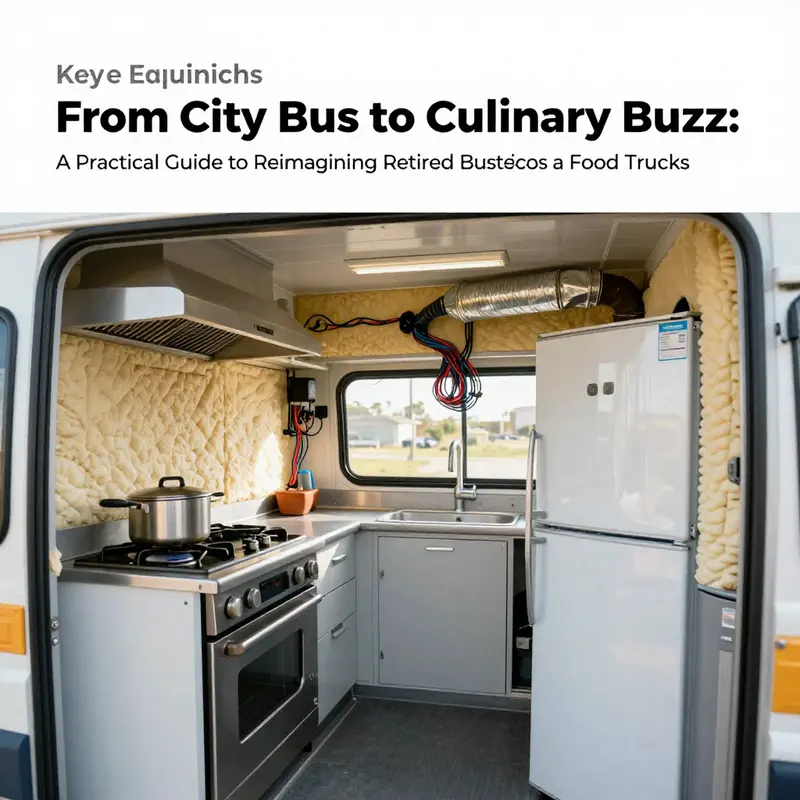

Beyond these core considerations, the assessment must address practical logistics: water supply, waste management, HVAC needs, and interior ergonomics. A bus destined to function as a street-front kitchen should accommodate a freshwater supply and a greywater system that complies with environmental standards. If municipal connections are available, plugging into mains power and water can simplify operations, but in many cases a self-contained system is necessary. Insulation and climate control are not mere conveniences; they determine year-round usability and staff comfort. In Harbin and other cold-weather cities, some projects have experimented with advanced insulation materials that improve heat retention and create a hospitable interior for staff and customers alike. Lighting, too, matters. LEDs at service counters and ambient accents not only improve visibility but contribute to the brand’s atmosphere. The interior design should therefore be considered in tandem with the functional requirements. A well-planned interior supports safe cooking, sanitary handling, straightforward cleaning, and an inviting customer experience, all while staying compatible with the bus’s original structure.

If the bus has a strong potential but requires targeted interventions, the assessment yields a phased plan rather than a single leap. A practical route might involve addressing structural and safety concerns first, then scheduling interior modifications, followed by power and plumbing installations. A staged approach minimizes disruption to the project and allows for incremental testing of workflows. It also makes it possible to calibrate the concept with real-world feedback, keep capital spending aligned with progress, and ensure that each step preserves the vehicle’s roadworthiness and compliance with local rules. Throughout this process, it is crucial to remain oriented to the community the project intends to serve. Whether serving residents with mobility needs, workers in busy corridors, or event-goers seeking a quick meal, the bus’s mission should guide every modification—from the height and reach of serving windows to the placement of staff stations and the location of waste disposal.

The assessment is not a one-off checkbox but a living blueprint that balances ambition with accountability. It requires collaboration with engineers, health inspectors, and city planners who can translate a concept into a safe, legal, and practical design. The aim is to arrive at a clear decision: proceed with a particular configuration, adjust the plan to accommodate constraints, or pivot to a different vehicle or service concept altogether. In practice, many successful conversions begin with a conservative, well-documented assessment that prioritizes safety, accessibility, and reliability while leaving room to evolve the kitchen and service model as the business learns from early operations. That balance between fidelity to the community’s needs and respect for regulatory realities yields a strong foundation for the chapters that follow, where design, branding, and operations come into sharper focus.

Finally, the journey from bus to food truck hinges on visitor-facing reality. A bus that promises accessibility, safety, and dependable service will earn trust quickly, and trust compounds into repeat business. The assessment, therefore, should matter not only to the builders and regulators but to future customers who will judge the bus by how well it delivers meals, how consistently it operates, and how thoughtfully it is integrated into the urban fabric. When the vehicle’s health aligns with a well-defined purpose, the project can move forward with clarity, budget, and momentum. The road from shell to street-ready kitchen is long, but with disciplined assessment, it becomes a coherent, executable plan rather than a series of risky, ad hoc changes. For readers charting their own path, the principle remains simple: know the bus, define the mission, and respect the rules that govern food on wheels. The rest—layout, equipment, and branding—will follow from that disciplined starting point. The journey from steel to sizzling meals begins with a clear, enforceable assessment of vehicle health and mission, ensuring that the dream of a mobile, community-serving kitchen is grounded in reality as much as imagination. For those seeking a structured starting point, remember that the assessment informs every subsequent choice, and it is the compass that keeps the project on course through redesigns, permits, and the first day of service. The bus becomes a platform not only for food but for responsible entrepreneurship that honors safety, accessibility, and urban life. External reference: https://www.pacificauto.com.cn/

From Bus to Permit-Ready Kitchen: Navigating Laws, Licenses, and Safeguards When Turning a City Bus into a Food Truck

The idea of converting a city bus into a mobile kitchen is seductive in its practicality and its promise of bold entrepreneurship. It suggests a radical, eye-catching way to bring food to the street, to communities that crave novelty, and to neighborhoods underserved by traditional brick-and-mortar dining. But the dream meets the reality of a dense, often unforgiving regulatory landscape. A successful conversion is less about clever retrofits and more about disciplined compliance, careful planning, and a proactive relationship with the authorities who guard public health, road safety, and urban order. When you embark on this journey, you are not simply reimagining a vehicle; you are reimagining how urban commerce intersects with safety standards, licensing protocols, and zoning rules. The path is navigable, but it requires patience, precision, and a willingness to align design choices with stringent requirements from the outset.

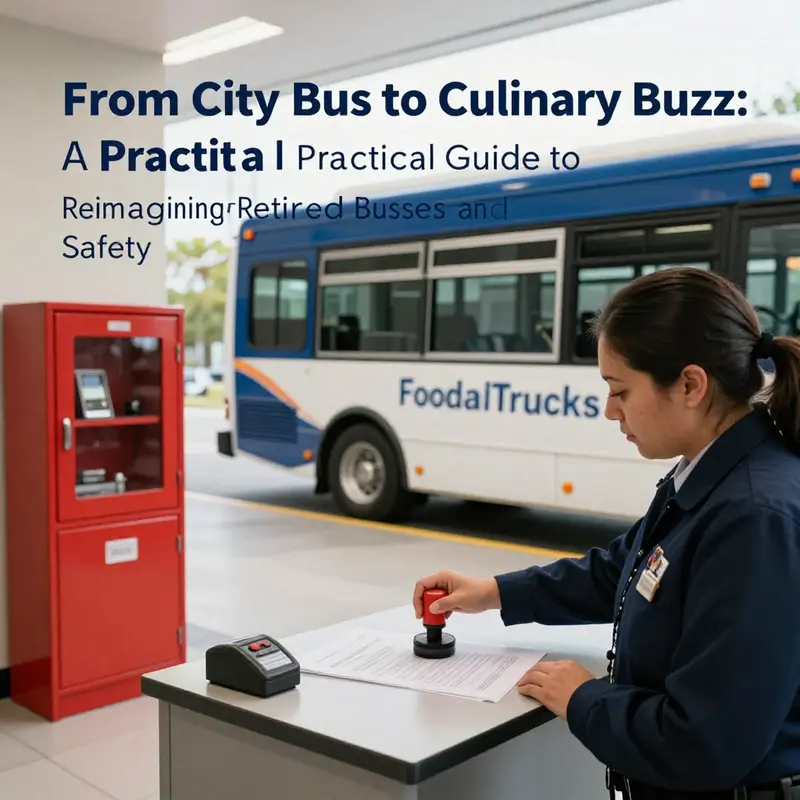

The foundational truth is that permits and licenses form the backbone of a legal operation. A city bus transformed into a food facility must first earn the right to exist as a legal entity that can prepare and serve food in public spaces. Across jurisdictions, the starting point is a formal engagement with the local health department to obtain a Mobile Food Facility Permit or its equivalent. This permit process is not an obstacle course to be endured after the build; it is a document that defines what the bus must be capable of doing safely and hygienically. It typically involves submitting a detailed plan that lists the kitchen layout, equipment specifications, water supply and drainage strategies, waste disposal procedures, and the anticipated menu. The authorities will assess whether the design supports safe food handling, whether there is enough space for handwashing, whether the refrigeration and cooking equipment are properly vented, and whether the overall footprint complies with safety norms for commercial kitchens. In many places, the permitting process also requires a food facility plan review before any modification to the vehicle is approved.

Alongside health department oversight, the vehicle itself must meet transportation safety standards. Structural changes, even when they seem routine, are subject to building code approvals and, in some cases, formal modification reviews. The rule is clear in many jurisdictions: you cannot alter the vehicle’s load-bearing elements, emergency exits, or fundamental safety systems without authorized review and documentation. This is not about stifling creativity but about ensuring that a bus repurposed for food service does not compromise transport safety or public corridors. Getting a DMV inspection and clearance can be a decisive milestone. Some regions require emissions testing or other vehicle-safety certifications to confirm that the converted bus remains roadworthy and compliant with current standards for passenger or commercial vehicles.

Fire safety sits near the top of the list in every compliance framework. A high-quality fire suppression system, appropriate extinguishers, and well-placed smoke detectors are not decorative add-ons; they are essential safeguards for kitchens on wheels. The ventilation system must be capable of handling the byproducts of cooking, and the exhaust must be properly vented to the exterior in a way that prevents grease accumulation and fire hazards in urban environments. Sanitation and waste management are another critical piece. A compliant operation needs a reliable freshwater supply, a properly equipped sink, and a robust system for handling graywater and solid waste. In many jurisdictions, inspectors will expect to see deflection plans, backflow prevention measures, foul-water containment, and accessible clean-out points that facilitate routine maintenance.

Beyond the obvious health and safety checkpoints, the regulatory journey extends into environmental stewardship and product integrity. Local environmental standards often demand the use of eco-friendly materials, proper waste segregation, and careful control of emissions and odors, especially in densely populated areas or near residential zones. These requirements influence everything from the choice of countertop materials to the placement of grease traps and the routing of electrical cables. Designers who begin with compliance in mind tend to reduce costly redesigns during inspections and avoid last-minute delays that can upend launch timelines. A well-thought-out compliance mindset helps you balance performance with portability, ensuring that the bus can operate cleanly in diverse neighborhoods and at varied events.

Zoning and parking regulations add another layer of complexity. Many cities designate specific zones where mobile food facilities may operate and often limit operations in residential districts or near certain institutions. Pre-approval for locations might be required, and there can be time-of-day restrictions, permit stacking with street openings, or caps on the number of permits issued per district. The practical effect is that the most compelling concept—the bus offering gourmet tacos, artful pastries, or regional specialties—must still fit within the city’s map of permitted spaces. This reality underscores the importance of early location scouting and ongoing dialogue with planning or zoning offices. Planning teams should map out potential routes and sites, then confirm with authorities which ones align with current rules and which require variances or additional approvals.

In this reality, the design decisions you make at the outset can reduce friction later. The interior layout should reflect not only efficiency for cooking, serving, and cleaning but also compliance-driven workflows. For instance, the placement of the sink and handwashing station must support hygienic practices as well as inspection readiness. The electrical system should be designed to accommodate peak loads during service, with clear separation between high-draw equipment and safe power distribution that inspectors can verify. The choice of ventilation, fire suppression, and waste management systems should be documented with technical specifications, installation diagrams, and maintenance schedules. It is not unusual for inspectors to request as-built drawings, equipment inventories, and proof of professional installation when evaluating a converted bus. Having these documents prepared in advance saves time and demonstrates a commitment to safety and reliability.

The real-world examples in the field illustrate the operational consequences of regulatory diligence. In many cities that actively support mobile food vendors, a careful, well-documented permit journey translates into smoother operations and fewer shutdown risks. The process often includes a series of phased inspections: plan review, equipment verification, a pre-operational inspection, and finally an annual renewal that confirms continued compliance. In some locales, environmental health officers will require periodic updates on equipment performance, water quality, and waste handling, creating a feedback loop that keeps the operation aligned with evolving standards. An orderly approach to inspections—one that treats them as milestones rather than hoops—helps operators anticipate costs, schedule staff training, and maintain a consistently safe customer experience.

The learning curve is not merely administrative. It informs every practical choice, from the size of the kitchen to the type of service window. The legal framework tends to favor straightforward, maintainable systems. For example, the decision to install a compact, purpose-built kitchen setup with clearly labeled zones for cooking, cooling, washing, and serving can streamline both compliance checks and vendor repairs. It also makes it easier to train staff and to document routine cleaning and maintenance. A bus retrofitted with modular, standards-compliant components can adapt to different menus while preserving the ability to pass audits with relief and confidence. The elegance of a compliant design is that it supports a resilient operation: safer for staff, more trustworthy for customers, and less prone to disruptive enforcement actions.

To bridge theory and practice, consider the guidance offered by a city known for its robust regulatory framework. In this context, a practical route is to treat the permitting process as a collaborative conversation with local authorities. Begin with an intake meeting where you present your concept, your anticipated menu, the bus’s physical constraints, and a preliminary equipment list. Be prepared to adjust layouts to accommodate plan review feedback. Seek early clarity on whether your vehicle requires a dedicated venting system, the type of fire suppression that will be accepted, and the standards for water supply and drainage that inspectors will expect. Document all decisions and retain copies of submissions, approvals, and correspondence. In this approach, compliance is not a checklist you chase after the build; it is an ongoing dialogue that informs design, construction, and daily operations.

For readers seeking a structured reference point, a well-documented municipal guide can illuminate the path. In San Diego, a comprehensive framework exists for navigating the food-truck permitting landscape. The guide outlines the steps to obtain the Mobile Food Facility Permit, the health department expectations, and the mechanics of inspections and renewals. It serves as a practical blueprint for operators who aim to balance creativity with accountability. While every city has its own flavor of rules, the core principle holds universally: safety, sanitation, and accountability drive the permit process, and smart operators thread these principles through every phase of their project. For readers who want a concrete, jurisdiction-specific example, this framework provides a valuable reference point while you pursue the unique requirements of your own city.

To summarize the regulatory journey, the bus-to-truck conversion demands more than an inventive design. It requires a disciplined approach to permits, vehicle safety, fire protection, sanitation, and zoning. A thoughtful integration of these elements from the earliest planning stages pays dividends in reliability, customer trust, and long-term viability. The goal is not merely to pass inspections but to sustain a safe, compliant operation that can adapt to different neighborhoods, seasonal demand, and evolving regulatory expectations. The more proactive you are in aligning your concept with the regulatory framework, the smaller the risk of expensive reworks, delays, or shutdowns. The result is a mobile food experience that honors the community it serves while standing up to the rigorous standards that cities demand of public health, safety, and urban order. For further reading and a practical regulatory reference, see the broader guidance linked below and the internal resource cited earlier in this chapter.

Internal resource: For more context on how regulations shape food-truck ventures, you can explore the discussion at navigational resources that address the regulatory terrain and best practices for staying compliant as you grow. Navigating Food Truck Industry Regulations.

External resource: Detailed municipal guidance on permits and inspections may be found at a jurisdiction like San Diego’s food truck permitting framework, which offers a practical snapshot of the processes involved and the expectations for facilities, equipment, and upkeep. https://www.sandiego.gov/business/food-truck-permitting

null

null

From Bus to Bistro on Wheels: A Unified Approach to Designing, Branding, and Operating a City-Converted Food Truck

The idea of turning a city bus into a food hub is more than a clever reuse of idle infrastructure. It is a choreography of design, safety, branding, and urban rhythm. The bus, once a vessel moving people from point A to point B, becomes a moving kitchen and social space that travels through neighborhoods, parks, and transit hubs with the same predictability and reliability that drew commuters to the route in the first place. The challenge is to weave function and personality into a compact, compliant, and market-ready unit. A successful conversion begins with a clear sense of purpose: will the vehicle serve a fixed route in a neighborhood market, or will it roam as a pop-up in parks and event spaces? The answer shapes every practical decision from the layout to the power supply, from the ventilation system to the branding strategy. The design must respect the bus’s structural realities while redefining its interior as a safe and efficient kitchen, a serving counter, and a controlled customer experience. In a well-executed conversion, the interior is not merely a space; it is a process that guides cooks, servers, and customers along a smooth, legible flow. The core principle is safety through thoughtful zoning. Take the preparation area, the cooking zone, the cold storage, the dishwashing station, and the customer window as distinct sections that still feel coherent as a single unit. Each zone is sized to minimize movement, reduce cross-contamination, and maintain clean-to-work turnover. This is not about cramming equipment into a shell; it is about designing a defined rhythm that matches a compact footprint with the pace of a bustling kitchen. The right zoning also supports compliance. Health authorities demand robust ventilation to manage heat and fumes, fire suppression capabilities, food-grade surfaces, and a grease management plan that prevents clogs and odors from seeping into the customer area. The interior materials themselves carry the weight of compliance. Stainless steel surfaces, safe for contact with food, are standard for prep tables and cooking surfaces. Durable, non-porous coatings protect against moisture and stains, while easy-to-clean floors and splash guards keep the workspace sanitary. The bus’s original seating is removed, but the structure remains capable of supporting a high-traffic, weather-exposed operation. That demands a careful approach to durability. Modern fabrication techniques enter the picture here, not to create novelty but to ensure longevity in outdoor environments. Precision laser-cut components produce clean, consistent joints and components that align with tight tolerances. CO₂ shielded welding creates strong, sanitary welds that resist corrosion and stand up to the vibrations and bumps of city streets. An electrostatic coating provides a weatherproof finish that holds up to rain, sun, and road grime. The hardware choices also extend to the powertrain and utilities. Electric or hybrid systems are increasingly popular for food-vehicle conversions because they simplify licensing, reduce emissions, and offer the possibility of external power connections or vehicle-to-grid opportunities. The prospect of V2G—drawing power from the bus back into the grid during off-peak times—may look like science fiction in some contexts, yet it is becoming a practical consideration for fleet operations and city street networks. The engine and drive components can be selected to minimize noise and vibrations, creating a more comfortable experience for staff and diners alike. A quiet, stable platform enhances safety, reduces fatigue, and supports a more predictable service cadence. Power distribution must align with the kitchen demands. A robust electrical system feeds a compact but capable kitchenette: a refrigerator that can operate reliably in fluctuating temperatures, a vent hood with a properly sized exhaust, and a stove or griddle that can perform under demanding lunch and dinner rushes. Generators provide independence in pop-up configurations, while a shore connection or a solar array can support extended daytime service in parks and transit corridors. The plumbing and waste management system demand equal attention. A freshwater tank and a greywater collection system are vital for compliance and hygiene when municipal connections are not readily available. The layout should place the wash area in proximity to the sink, with a clear path to cleaning and sanitizing stations to maintain turnover speed while upholding health standards. Even the water temperature and pressure must be designed to accommodate daily dishwashing cycles and handwashing with minimal downtime. Ventilation is not a decorative feature but a practical requirement. Proper exhaust and intake vents manage heat, smoke, and odors and must be calibrated to local codes. The result is a kitchen that feels slightly larger than its physical footprint because air moves efficiently, keeping temperatures manageable during peak service hours. Climate control inside the bus is another critical factor. The harsh realities of external weather demand insulation and climate-control strategies that keep staff comfortable and food quality stable. Advanced insulation materials, along with strategic use of heating and cooling elements, help maintain consistent operating conditions across seasons. A thoughtful interior also supports the customer experience. The service window, positioned at customer height, becomes the main interface with the public. It is not a mere window; it is a designed point of contact that carries the brand’s voice and creates a sense of welcome. The exterior design must connect with pedestrians in a few seconds of glance as the bus rolls into a location. A strong brand is essential, and it should be legible from a distance, with color blocks and typography that convey the menu at a glance. Exterior storytelling can be as simple as a color language that ties to a cuisine concept or as elaborate as murals that echo local culture. The bus’s silhouette remains its most recognizable asset, and many projects honor that heritage rather than erase it. A branded wrap or paint scheme can preserve the chassis’s shape while signaling the kitchen’s personality. Interiors, too, deserve careful curation. A boutique or café-like mood can transform the interior from a mere workspace into a social space, inviting customers to linger after receiving their orders. The aesthetic approach should balance visibility and readability. Clear signage helps passersby understand what is being served, what prices look like, and where to line up. Aesthetics are not only about appearance; they influence behavior. A strong, cohesive visual identity invites return visits, creates a sense of trust, and anchors the bus within the city’s food-scape. The branding itself should be anchored in the city’s character, folklore, or neighborhood identity. The best brand stories are built around place, not just product. This is where the internal link to branding guidance becomes useful. A solid reference is Cognitive guidelines for graphics and identity on mobile food spaces, which provides practical pathways for creating a distinct yet legible look that works on a moving canvas like a bus. For those interested in the branding side, exploring the broader ideas behind “Branding on Wheels” can help shape a strategy that is both recognizable and adaptable. See Branding on Wheels: The Ultimate Guide to Food Truck Graphics and Identity for deeper insights into color, typography, and wrap design, which you can explore here: https://loschifladostruck.com/branding-on-wheels-the-ultimate-guide-to-food-truck-graphics-and-identity/. Beyond aesthetics, operations determine whether the bus can become a sustainable business. A bus-based food venture benefits from a networked approach in which multiple conversion units share best practices, equipment standards, and a service ethos. The deployment model might be a fixed-route bus that serves daily neighborhoods, a mobile pop-up that parks near transit hubs or events, or a hybrid that rotates through several locations on a schedule. Each pattern carries different implications for staffing, scheduling, and maintenance. A fixed-route model offers predictability, which helps with staffing and supply chain planning, while a pop-up model emphasizes flexibility, accessibility, and community engagement. In either case, the kitchen layout must support quick service and sanitation. A “line in the bus” approach—where the cooking and plating occur along a single, logical line with minimal back-and-forth—reduces steps, keeps traffic moving, and shortens the time from order to pickup. This efficiency is essential in busy urban contexts where every minute counts. The operational planning must also consider regulatory requirements. Local health departments demand permits for food service operations, vehicle certifications, and compliance with street-use rules, which may govern where and when a bus can park or operate. The process can be navigated more smoothly with a multidisciplinary approach that includes health and safety professionals, city planners, and, when necessary, legal counsel. Training staff becomes a vital component of reliability. Food safety certification, familiarity with the bus’s unique workflow, and quick-clean protocols ensure that turnover remains high and quality remains consistent. The staff’s experience is amplified when the kitchen’s design reduces friction. A well-planned interior minimizes unnecessary movement, keeps hot surfaces out of staff’s reach, and enables staff to clean as they work without interrupting service. The customer experience benefits from a calm, predictable rhythm, a clear order process, and a welcoming environment. The bus itself can become a storyteller, telling the city’s food-story in a new voice. The city’s pace, the changing light, and the surrounding streets all contribute to how the bus is perceived. The end result should be more than a vending window; it should feel like a temporary neighborhood restaurant that travels through time and space, linking residents to fresh, affordable meals without requiring them to leave their daily routes. In the long run, a successful conversion demonstrates how a public asset can be reimagined as a flexible, inclusive urban service. The combination of advanced fabrication, adaptive branding, and scalable deployment models aligns with the city’s ambitions for sustainable, local economies and improved access to food. While each city will have its own regulatory constraints and logistical realities, the underlying principles remain the same: design for safety and efficiency, brand with clarity and character, and deploy with an eye toward adaptability and resilience. This approach reduces waste, extends asset value, and invites communities to reframe transportation infrastructure as a platform for nourishment and connection. For researchers and practitioners who want a broader context, the literature and case studies on city bus cafes and mobile markets offer a rich frame for understanding how these ideas translate into urban practice. A notable public report highlights how such initiatives have emerged in multiple cities, emphasizing their role in addressing food security, mobility, and urban vitality while prioritizing safety and sustainability. For further reading, see the China Daily coverage of bus-based food concepts in Chinese cities, which provides a broader panorama of design, aesthetics, and operations in practice: https://www.chinadaily.com.cn/china/2024-12/28/content_41795372.htm

Final thoughts

Converting a city bus into a food truck is a journey that blends imagination with structure. By starting with a clear assessment of what you want to achieve, securing the right permissions, equipping a compact yet capable kitchen, and finally shaping a design and operations plan that honors your audience, you turn a retired vehicle into a community asset. The bus becomes a flexible platform for events, corporate gatherings, and neighborhood connections—an adaptable dining room on wheels that travels where it matters most. With careful planning, a dash of creativity, and ongoing attention to safety and guest experience, your mobile canteen will not only feed people but also foster conversations, collaborations, and lasting memories.