Powering a food truck on the go is as much about preparation as it is about flame and flavor. When you’re serving hungry crowds at festivals, corporate events, or neighborhood gatherings, the last thing you want is a power hiccup that stalls the grill, freezes the specials, or trips the line of excited guests. The right generator size sits at the heart of dependable operation: it must comfortably handle your continuous running loads—like the grill, fryers, refrigerators, and hot holding units—while also accommodating startup surges from motors and pumps that grab extra power for a moment as equipment starts. This balance becomes even more important in mobile or urban environments where noise, fuel efficiency, and clean power matter for client satisfaction and compliance. In the chapters ahead, you’ll discover a practical, phased approach to determine your needs, compare standard and inverter options, account for startup surges with a safe margin, and apply real-world guidelines to keep your kitchen humming smoothly from street corner to event site. Each chapter connects back to the central question: What size generator do I need for my food truck? By the end, you’ll have a repeatable method you can use before every event, plus actionable tips for selecting units that deliver stable, clean power without breaking the bank or the neighborhood serenity.

null

null

Sizing the Mobile Kitchen: How to Choose Between Standard and Inverter Generators for a Food Truck

When you strip a food truck down to its essentials, the engine that keeps the kitchen humming is a generator. It isn’t just about matching a number to a list of appliances; it’s about understanding how those appliances behave once they wake up. A food truck runs on a delicate balance between continuous power and the surge power required when motors start, compressors engage, and pumps come online. Most operations fall into a practical range where a continuous load of roughly 5,000 to 7,000 watts can cover the main cooking equipment, refrigeration, and hot holding for a busy day. But the startup reality is louder than the steady hum. Motors and compressors typically draw 30 to 50 percent more power at the moment of ignition. That surge is why the sizing conversation rarely ends with a single running wattage. It ends with a margin, a cushion, a guarantee that the equipment won’t overload, stall, or trigger nuisance trips when a door swings, a fryer starts, or a hose of hot water leaps into action.

To translate these numbers into a practical decision, begin with a clear map of your electrical footprint. List every piece of equipment, note its running wattage, and, crucially, identify any high inrush appliances. A commercial deep fryer, for instance, may operate at a few thousand watts but can spike up to around 4,500 watts at startup. A large commercial refrigerator might pulsedly require substantial current when the compressor first kicks in. When you aggregate these demands, you’ll often find a running load near 6,000 watts for a typical setup with multiple cooking stations, a refrigerator, and a hot hold unit. The key rule of thumb is simple: plan for 30 to 50 percent more than your running total to cover startup surges. If your baseline draw is about 6,000 watts, aiming for an 8,000 to 9,000-watt generator provides a comfortable buffer against overload and ensures the system can handle peak demand without hesitation.

Beyond the numbers, the choice between standard and inverter generators matters for power quality, efficiency, and the kind of operating environment a food truck encounters. Standard generators, built to deliver constant output at a fixed speed, tend to generate more voltage fluctuation and produce what specialists call “dirty” power. That is rarely a problem for heavy-duty older equipment, but it can be a risk when a truck depends on sensitive electronics—the digital thermometers you rely on, POS systems, tablet devices, and the like. Inverter generators, by contrast, are designed to produce clean, stable power. They do this by converting AC to DC, then back to a stable AC output, and they automatically adjust engine speed to match demand. As a result, they typically deliver what cooks and managers value most in a mobile setting: consistent voltage, lower total harmonic distortion, and less risk to precision electronics. The engine’s workload responds to the kitchen’s real-time needs, which keeps fuel use down and noise down—an important factor in urban neighborhoods and near residences where noise can influence customer experience as much as price or menu.

Those advantages, however, come with trade-offs. Inverter generators tend to carry a higher upfront price and often a smaller maximum wattage per unit compared with traditional powerhouses. In a kitchen with multiple high-wattage appliances—an expansive griddle, a high-capacity oven, several cold storage units—the total wattage and surge may exceed what a single compact inverter can comfortably supply. In such scenarios, a well-chosen combination can work better: one or more inverter units for the sensitive loads and a larger, surge-capable standard unit for the heavy hitters, or a single larger standard generator that still has ample surge capacity tailored to your equipment list. The practical decision hinges on the actual equipment roster, how frequently you operate near peak electrical demand, and whether you prioritize quiet operation and power quality for electronics over raw, all-day power at a lower initial cost.

To ground this in a concrete decision framework, consider a representative scenario. Suppose your truck’s continuous draw sits near 6,000 watts due to a couple of cooking stations, refrigeration, and a hot holding cabinet. If you opt for an inverter-only approach, you would need a unit or a cluster of units capable of delivering at least 8,000 to 9,000 watts total with room to spare for startup surges. If you lean toward a standard generator, you’d still want enough surge capacity to handle the same startup events but with a larger single unit—one designed to sustain that higher continuous load and deliver stable current during motor starts. Either path works, but the decisive factors are how much you value clean power, how many sensitive devices you’d like to protect, the cookie-cutter or custom nature of your equipment lineup, and how much you’re prepared to invest upfront.

A practical approach to making the call is to perform a meticulous, bottom-up calculation that factors in both running watts and startup surges, then tests the math against two real-world constraints: reliability in mobile contexts and tolerance of the urban operating footprint. Inverter generators excel in reliability when the load is variable and includes electronics. They excel in noise reduction, which matters when your truck operates near residential areas or during late-night events. If your menu features big, continuous loads—think a heavy griddle occupying a large portion of your electrical footprint, combined with multiple cold storage units—the temptation to consolidate with a single larger standard unit becomes stronger. In such cases, you’ll want a generator with a robust surge rating and a higher rated continuous output to prevent overload during peak moments when every surface heats up and every slot in the grill switches on. The objective is to prevent the engine from hitting a ceiling where it cannot deliver the startup current without dropping voltage or triggering shutdown.

In practice, the choice is rarely about one feature in isolation. It’s about how the generator behaves under real kitchen conditions. Inverter models deliver the clean power that protects sensitive devices like POS terminals and digital thermometers, which means fewer errors and less downtime. They also adjust output to the load, which translates into quieter operation and better fuel efficiency. Standard machines, by contrast, provide more raw power at a lower initial cost and may be more robust for continuous, high-wattage cooking equipment where startup surges are predictable and manageable within the unit’s surge rating. For a truck with a mix of high-wattage appliances and several cooling units, the math may point toward a standard generator capable of delivering strong surge capability, paired with careful load management and perhaps a dedicated phase for the refrigeration circuit to minimize simultaneous startup demands.

As you weigh these options, you should keep your operating environment in view. Mobile settings introduce variables that static shops do not face: variable fuel availability, altitude, ambient temperature, and the need to be discreet about noise. Inverter generators tend to be lighter and more portable, which matters when you move between events, parks, or trucks in tight curbside spaces. They also can be stacked in multiple configurations to cover higher loads when a given event calls for it, so long as the total system remains within safe limits for the electrical feeds and the truck’s distribution panel. But the list price, maintenance considerations, and the potential need for several units to cover a high-demand kitchen are practical realities that influence the decision.

To the reader who wants a path through the complexity, the prudent move is to build a precise equipment list first, then compare two scenarios: one driven by the inverter approach and one by the standard approach, each sized with a deliberate safety margin for startup surges. The outcome should be a recommendation that aligns with your menu, your service style, and your budget. For a broader, more technical walk-through that anchors this decision in performance, features, and real-world applications in mobile kitchens, you might refer to a comprehensive guide on generator sizing for food trucks. This resource emphasizes how power quality, surge handling, and practical testing shape the final choice, and it reinforces the idea that there is no one-size-fits-all answer—only a precise fit for your operation.

If you’re ready to translate these principles into a concrete plan, you can start by examining your equipment list and exploring how the two generator philosophies match your needs. And as you examine your options, a deeper dive into the model choices—how your truck’s electrical footprint interacts with the kitchen’s rhythm—can be enlightening. For a detailed view on how to balance performance, technical features, and real-world applications in food trucks, you can consult a respected reference in this field. In the meantime, consider this practical nudge: when you map your electrical demands, keep a generous cushion for startup surges, verify every appliance’s startup and running wattage, and remember that the right generator choice is as much about reliability as it is about cost. The right choice ultimately supports your service consistency, your guests’ experience, and your business’s resilience on the road.

Internal resource: To tailor these concepts to your specific setup, a closer look at how to choose the right food truck model can be helpful. Learn more here: Choosing the right food truck model.

External reference: For a detailed, performance-focused guide on generator sizing for food trucks, see the external resource here: https://www.generac.com/food-truck-generator-guide

Sizing Power on the Move: Startup Surges, Safety Margins, and the Right Generator for Your Food Truck

Power is the invisible backbone of a mobile kitchen. When you pull into a busy curb line or park near a bustling event, your ability to serve clean, consistent food depends on a generator that meets both the steady heartbeat of your equipment and the sudden, demanding bursts that start each appliance. Getting this right isn’t about chasing the biggest number you can fit on a price tag. It’s about matching the actual running load of your kitchen, anticipating startup surges, and building in a buffer that keeps everything running smoothly even if plans change or the day grows longer.

In practical terms, most food trucks run on a generator in the 5,000 to 7,000-watt range. That range isn’t arbitrary. It aligns with the core needs of the majority of cooking rigs: a grill that maintains sizzle, a fryer that keeps up with demand, and cold storage that preserves safety and quality. But every piece of equipment also carries a startup demand. Motors in compressors, pumps that circulate refrigerant, and fans that pull heat away from hot-holding units can draw 30 percent to 50 percent more power for a brief moment as they first start. If you size your generator only for the running load, you risk flipping the switch on a busy service and watching lights flicker, burners falter, or, worse, disrupting a day’s business.

That is why the recommended practice comes down to a simple rule of thumb: plan for a 30 to 50 percent safety margin above your total running load. This is not a luxury; it’s a practical safeguard. Imagine your equipment runs at 6,000 watts on an average cycle. If you add 30 to 50 percent as a cushion, you should be looking at a generator in the 7,800 to 9,000-watt neighborhood. The idea isn’t to oversizedly tote an engine that trades performance for fuel economy; it’s to ensure you have the headroom required to handle startup surges without sacrificing service quality or risking a blown fuse in the middle of dinner rush.

This approach also keeps future growth in mind. A truck that plans to expand its menu or run more display refrigeration, additional hot-holding units, or longer service hours benefits from extra buffer. It’s far easier to design your kitchen around a slightly larger generator from the start than to retrofit later when business expands and the same startup events threaten to overwhelm your system. The numbers are not just about surviving a surge; they are about sustaining the rhythm of service, keeping staff focused on cooking and customer service rather than troubleshoot mode.

Choosing the exact model of generator matters because of how power is delivered. Inverter generators have become the preferred option for food trucks, especially when operating in urban cores or near residential zones. They deliver what’s commonly termed “clean power.” The inverter’s process—converting AC to DC and back to a stable AC output—helps smooth out voltage and current. The result is less stress on sensitive electronics: point-of-sale devices, digital thermometers, and timing systems work more reliably when they aren’t hit by sudden voltage spikes. Inverter units also automatically adjust engine speed to match demand. That means less noise, lower fuel use, and a level of efficiency that standard, fixed-speed generators simply can’t match. For a mobile kitchen, where every decibel matters and fuel costs add up, that efficiency translates into longer days between fill-ups and more time serving customers.

But the practical steps don’t end with buying the right kind of generator. You need a method to translate your kitchen’s needs into a trustworthy specification. Start with a complete list of running watts for every major piece of equipment, from the stove and oven to the refrigeration system and any hot-holding equipment you depend on to keep sauces and soups at safe temperatures. Then identify the startup watts, or surge power, for each device. Some devices may have modest surge requirements, while others, such as compressors, may dominate startup demand. Add the running watts together, then apply the 30–50 percent margin to derive your target continuous rating. Finally, allow for a little extra space for the unexpected: a fan, a blender that you add during peak hours, or a case where the shop needs to power a small charger or light during a late service. The math is straightforward, but its impact is transformational. It determines how often you can serve at full speed without pausing to reset breakers, and it affects your overall energy strategy, including how you schedule rest periods and how you think about backup plans during a busy event.

In practice, the approach translates into a narrative you can explain to investors, partners, or lenders. You’re not chasing a single, absolute wattage; you’re describing a system designed to absorb variability. A buffer of 30 to 50 percent gives you the elasticity to handle a worst-case surge scenario—such as a compressor starting up exactly as you’re pulling a new batch of fries from the fryer—without cascading into a multi-appliance shutdown. It also provides room to grow. If you’re considering adding an additional refrigeration unit, more hot-holding shelves, or a dedicated beverage station in the future, that extra cushion will keep you from revisiting the entire power plan sooner than you want to.

The moral here is simple. Size your generator to cover the running load plus a deliberate surge-and-safety margin, favor inverter technology for power quality and efficiency, and make sure you have a plan that accommodates growth. The process is not about picking a number in a vacuum. It’s about building a robust system that maintains service quality in the face of startup dynamics and shifting menus. If you’re looking to anchor these decisions in practical, industry-informed guidance, the choice aligns with the broader strategy of how you design your kitchen and how you set up your daily operations. As you refine the layout and select equipment, consider how the electrical footprint will evolve with your menu, and incorporate that understanding into how you configure your generator capacity.

For those who want to anchor this planning in a real-world framework, the topic naturally intersects with the broader question of how to choose the right food truck model. See how the electrical backbone aligns with layout choices and equipment planning in the detailed guide on selecting the best kitchen arrangement and truck configuration. This integration—how you physically arrange your space and how you power it—helps ensure that the generator you choose fits not only today’s needs but the shape of your business tomorrow. Choosing the right food truck model.

Ultimately, the practical payoff is reliability and consistency. A properly sized, efficient inverter generator with a generous startup margin reduces interruptions, protects sensitive electronics, and supports a calmer, more predictable service rhythm. It gives you the latitude to serve high-quality meals without the anxiety of electrical overload during peak hours. It also means your crew can focus on the craft—perfecting the sear on a steak or the precise glaze on a pastry—rather than worrying about whether the power will hold when the grill first roars to life or a refrigeration compressor kicks in. In a field where timing, temperature, and taste converge to define success, that kind of confidence is priceless.

For a deeper dive into how to translate this planning into concrete, real-world guidelines—complete with wattage charts and equipment-specific surge profiles—there is a comprehensive, practical resource that walks you through the calculations and choices. It offers practical examples and a framework you can adapt to your own kitchen. For a thorough, real-world guide, see this resource: https://www.foodtruckpower.com/generator-guide

Power on Wheels: Generator Sizing for Food Trucks in Urban Settings

Power on wheels is about more than wattage. In a city block, a food truck needs a generator that covers running loads, startup surges, and stays quiet and efficient. Start with a complete inventory of running devices: refrigerators, freezers, hot holding, grills, fryers, and pumps. Running watts for these items in a compact truck typically fall in the 2000 to 4000 watt range when used together with lights and fans. However, startup surges can push demand higher, so plan with headroom. A surge margin of about 10 to 20 percent above your running watts is a prudent target for most setups. Inverter generators bring benefits in urban settings: cleaner power, load matching, and lower noise. Typical urban inverter ranges run from 2000 to 3500 watts, which covers most cooking and auxiliary loads with room for startup spikes. Always verify against manufacturer specifications and consider staggering nonessential loads during peak times. The goal is reliable, clean power that protects equipment and maintains a positive customer experience, even in busy streets. When choosing, also consider regulations and venues that affect noise and emissions. In practice, document your equipment list, calculate running watts, add surge cushion, and compare to continuous ratings of available models. If total runs toward the upper end of the 2000-3500 watt range, evaluate load staggering or slightly larger capacity to keep service smooth while avoiding overspending on capacity you do not need.

Sizing for Power on Wheels: Practical Rules for Matching a Generator to Your Food Truck Demands

Choosing a generator for a food truck is a test of practical math, real-world constraints, and the realities of moving cuisine. It isn’t enough to pick a number that looks big enough on a spec sheet. You must translate your kitchen layout, your equipment lineup, and your service model into a single, reliable energy plan that works under everyday use and in the occasional off-grid setting. At the core of this planning lie two concepts: running wattage—the continuous power your appliances need to stay on—and surge wattage—the extra kick they require when motors start up or compressors whirl to life. The most common guidance for mobile kitchens emphasizes a goal that blends both concepts. For many operations, a generator in the range of five to seven kilowatts can cover core cooking and refrigeration needs, but that baseline often proves too lean once startup surges are considered. Motors in compressors, pumps, and fans can demand thirty to fifty percent more power as soon as they wake up, and trucks traveling between markets rarely enjoy perfectly steady electrical conditions. The robust rule of thumb is simple: size for your total running load, then add a comfortable margin—typically thirty to fifty percent—to absorb startup surges without dipping into overload territory. In practice, that margin makes the difference between smooth service and the unsettling pause when a fryer rack or a refrigeration cycle demands a momentary burst of current. Inverter generators offer a compelling path forward here. They deliver clean power by converting AC to DC and back to a stable AC output, which protects sensitive electronics—from POS systems to digital temperature displays. They also adapt engine speed to the demand, trimming noise and fuel use, which matters in urban environments or neighborhoods with strict quiet zones. The logic is straightforward: you want consistent, reliable power that doesn’t destabilize the electronics you rely on for sales, while also preserving fuel and minimizing disturbance to customers and neighbors. To translate this into a concrete sizing exercise, start with a careful audit of your equipment and its startup behavior. A typical menu may feature a commercial griddle and a deep fryer, plus cold storage and point-of-sale lighting. The wattage of these items varies widely, and even the same class of equipment can behave differently depending on model and age. A commonly cited range for high-wattage appliances is broad: between seven and twelve kilowatts of overall capacity, depending on how you configure your cooking line, refrigeration, and ancillary devices. This wider band reflects the reality that some trucks run only a compact setup, while others pack multiple high-demand tools into a mobile kitchen. The core calculation is the sum of the running watts, plus the anticipated surges. For example, a typical dense setup might include a griddle at three and a half to five thousand watts, a deep fryer at four to six thousand watts, and a refrigerator that runs around eight hundred watts but can surge to about eighteen hundred during startup. Add a microwave around twelve hundred watts, a blender or mixer in the five hundred to one thousand range, and a POS system with lighting in the three hundred to five hundred range. When you add those numbers, you’re looking at a running load in the neighborhood of eight to ten kilowatts for steady operation, with a startup surge that can push total demand well beyond that figure. If the core appliances present a surge around eleven thousand watts, many operators choose a twelve-thousand-watt generator as a practical minimum, then apply the thirty-to-fifty percent margin to accommodate startup transients and potential future equipment. Yet while these numbers provide a solid framework, they are not a one-size-fits-all prescription. An inverter-based system that can scale its output to actual demand can be a smarter choice than a fixed, non-modulating unit. It reduces wasteful idle running and often delivers superior stability for sensitive devices, especially when you’re working in tight spaces or moving between venues with varying power conditions. In practice, the sizing decision also depends on the vehicle itself and the operational model. A larger, fixed, onboard generator or a dual-generator setup gives you redundancy and higher peak capacity, which can be crucial for trucks with a broad menu or those that operate at high-volume events. The trade-offs are real, though: heavier weight, higher upfront cost, and ongoing fuel burn. For smaller trucks or those built on compact platforms, a lower-capacity generator can be perfectly adequate if you carefully stage equipment and use energy-efficient appliances. The planning approach also benefits from considering future needs. If you anticipate expanding your menu, adding more refrigeration, or incorporating high-wattage devices like advanced beverage stations or multiple blenders, you should already plan for 15 to 20 percent more headroom than today’s peak requirement. These considerations become even more important when you operate in environments with strict noise regulations or where accessibility to fuel is intermittent. The practical takeaway, then, is clear: sum your running wattage, assess startup surges, compare with reputable generator sizing guidelines, and then add a margin that reflects your risk tolerance and your growth plans. An inverter generator is often the best starting point for a mobile kitchen that prioritizes both performance and responsible power delivery. It’s also worth noting that the exact figures you land on should be tested under real-world conditions. In a perfect test, you would run your equipment together, monitor the peak demand, confirm the startup sequence, and verify that the generator maintains voltage and frequency within design tolerances as devices cycle on and off. For operators who want a more structured framework, there are additional high-level resources that translate this method into calculators and equipment compatibility charts, offering case studies from peers who’ve already walked this road. For readers who are mapping their path from the blueprint to the street, this approach aligns with the broader guidance in the industry, which emphasizes reliability, power quality, and adaptability as the pillars of a successful food truck operation. If you’re curious about the specific features that help a generator meet food-truck needs—such as voltage regulation, waveform stability, and automatic idle control—these details matter when you’re choosing among different inverter models. When you pair a properly sized inverter with smart electrical planning, you gain not only operational steadiness but also resilience in the face of a blown fuse or a hiccup in a power source at a busy festival. The process is inherently iterative. Your first pass will establish a baseline, but as you gain hands-on experience with your kitchen’s rhythm, you’ll refine the configuration. It’s not unusual for operators to adjust their setups after a season or two, swapping in more efficient equipment, consolidating appliances, or adding an additional small generator for hot backup during prime events. If you want a navigable pathway to deeper guidance, you can explore resources that break down performance, technical features, and real-world applications for food truck power systems. For readers who prefer a concise road map that integrates calculations with equipment compatibility, a detailed guide on sizing and performance can be an invaluable companion as you finalize your choice. For further exploration, you might find it useful to examine the longer-form analysis offered by industry resources that lay out calculators, charts, and case studies from operators across North America. And if you are considering how your choice of truck model affects electrical planning, you may want to reference material on choosing the right food truck model for your concept and footprint. To connect with peers and read about real-world experiences, you can also explore targeted industry blogs and guides that address resilience, financing, and operations. For those who want a direct route to an internal discussion of equipment configurations, consider this linked guide on: Choosing the Right Food Truck Model. Choosing the Right Food Truck Model. This chapter sits within a broader conversation about how hardware choices shape electrical needs and the business outcomes you’re pursuing. In sum, the right generator for a food truck is less about chasing a single number and more about building a responsive, scalable power strategy that keeps your kitchen humming, your customers satisfied, and your crew focused on crafting great food rather than wrestling with outages. A disciplined approach—start with running watts, account for startup surges, apply a prudent margin, and lean toward inverter technology—helps you navigate the uncertainties of mobile service without compromising performance or profitability. External resources can further illuminate the path, including official guides that chart performance and application details for mobile kitchens. For a detailed, practical guide, see the official generator guide: https://www.generac.com/food-truck-generator-guide

Final thoughts

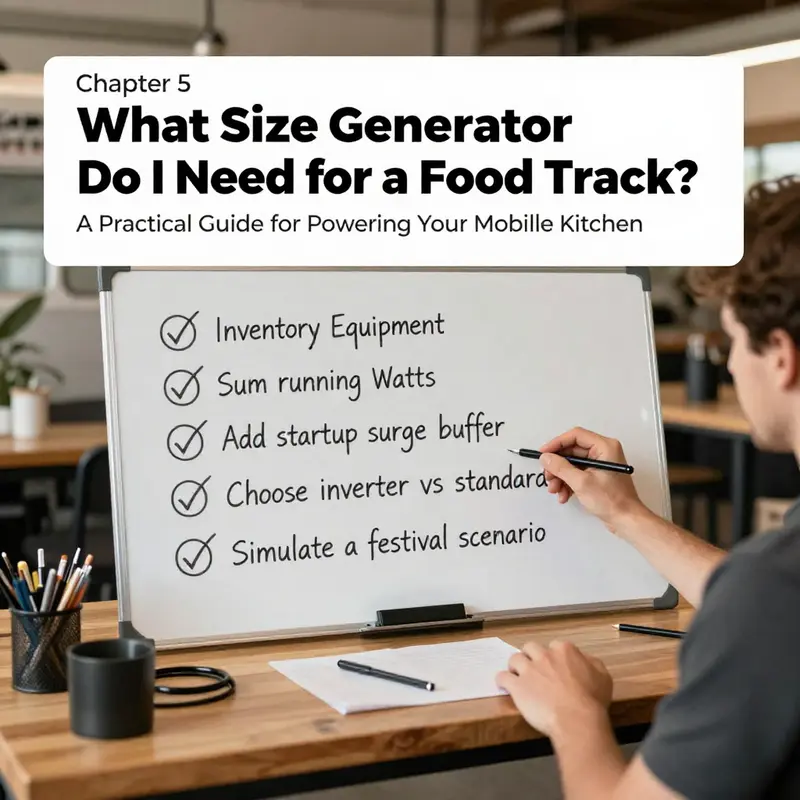

Sizing a generator for a food truck is about turning power into reliability, not guesswork. By separating continuous running loads from startup surges, and by choosing the right technology—especially inverter models when clean power and efficiency matter—you can operation a mobile kitchen with confidence. Remember to build in a sensible safety margin of 30–50% to account for motor starts and equipment aging. In urban environments, where noise and emissions can influence location and compliance, the quiet, efficient inverter option often shines, while standards may suit a fixed setup at larger events. Use the practical sizing steps outlined in Chapter 5 as a repeatable process for every event, season, or kitchen configuration. With thoughtful planning, your crew can focus on crafting memorable meals and experiences, not chasing power problems.