Bringing a food truck to life for events, corporate functions, neighborhoods, and culinary enthusiasts hinges on more than a killer menu. It hinges on navigating a patchwork of permits and licenses that shift by city, county, and state. The difference between a smooth launch and a stalled dream often comes down to preparation, timing, and relationships with local authorities. When planning a first event, you’re not just selling tacos or fusion bowls—you’re coordinating a legal journey that starts long before the first test fry and ends with a green light that lets your team season crowds, not red tape. This guide takes you through five essential chapters that align permits with practical outcomes: credibility, safety, and reliability. Chapter 1 focuses on Business License, Registration, and Legal Structure, because your legal identity shapes taxes, liability, and branding. Chapter 2 dives into Mobile Food Vendor Permits and Local Approvals, the day-to-day gatekeepers that unlock street corners and festival lots. Chapter 3 translates health rules into a kitchen that’s prepared for inspections and designed with compliant layouts. Chapter 4 makes certain every team member understands food safety and hygiene, so your guests are in good hands. Chapter 5 closes the loop with Health Inspections, Sales Tax, and Ongoing Compliance, ensuring that every passing score becomes a standard, not a one-off victory. As you move through each chapter, picture the big picture: a truck that’s legally sound, operationally smooth, and capable of delivering delightful experiences at events, corporate gatherings, community markets, and beyond. You’ll find practical checklists, decision points, and real-world examples tucked into each section, all aimed at helping planners, admins, and food lovers bring a mobile dining vision to life confidently. The permits journey isn’t a barrier to creativity—it’s a framework that empowers you to scale, partner, and host memorable moments without last-minute surprises. Let’s begin with the foundation that makes every permit possible: a strong business identity that’s ready to meet city and health authorities with clarity and consistency.

Permits as Foundation: Building the Business License, Registration, and Legal Structure for a Food Truck

Riding the growing tide of interest in mobile dining begins long before the first sizzle of a grill. It starts with the quiet, sometimes meticulous work of getting the foundations right—choosing a legal structure, registering a business name, obtaining an Employer Identification Number, and securing the local licenses that permit your wheels to roll. In essence, this chapter is about reimagining permits not as roadblocks but as the sturdy framework that keeps your operation compliant, sustainable, and ready to scale. The decision points you face here ripple through every other permit you will eventually file for, from the health checks to the tax registrations, because the shape you give your business at the outset determines how smoothly you can navigate inspections, liability, and finances down the line. At its core, forming a food truck business legally means aligning three intertwined threads: the internal structure of your enterprise, the external markers that identify and authorize it, and the practical systems that keep it compliant in daily operation.

First comes the question of structure. The choice is more than a tax convenience; it defines liability, ownership, and how you interact with investors, partners, or employees. A sole proprietorship is simple and inexpensive, but it places personal liability squarely at your feet. A partnership distributes shared responsibilities yet introduces how decisions are made and how disputes are resolved. A limited liability company, or LLC, blends pass-through taxation with liability protection, offering a shield against personal exposure while maintaining operational flexibility. A corporation introduces formalities and distinct layers of ownership, which can be advantageous if you envision rapid growth or bringing in outside investors. The right choice depends on your risk tolerance, funding plans, and how you want to handle profits and losses. While many single-owner food truck ventures begin as sole proprietorships or LLCs, the structure you select should be decided with a clear eye on future expansion, possible partnerships, and the taxes you’ll owe. Even this early decision affects how you file for other permits, how your name is registered, and how your bank accounts are structured, so it is worth thoughtful consideration from the start.

Once the structural decision is made, the next critical step is to register your business. Registration is not merely a ceremonial act; it creates a legal identity for your enterprise and confirms that your chosen business name is unique within your jurisdiction. In many states, this begins with registering a name—often called a doing business as, or DBA—so that the public record clearly reflects who is behind the operation. The exact home for this filing changes by state and locality: in some places, you register with the Secretary of State; in others, the local clerk’s office or the county recorder handles it. This is why it is essential to consult your local government’s business licensing office and to review the state-level processes. A clean, properly registered name lays the groundwork for branding, banking, and compliance, and it prevents confusion or disputes with other businesses that might share a similar moniker. In practice, this step is the bridge from an idea to a legally recognized entity that can legally enter contracts, lease a space, or comply with licensing and insurance requirements.

The federal dimension then comes into view in the form of an Employer Identification Number, or EIN. This nine-digit identifier is issued by the Internal Revenue Service and functions much like a social security number, but for your business. An EIN is indispensable for opening a business bank account, filing business taxes, and, if you hire employees, managing payroll and withholding taxes. Applying for an EIN is a straightforward online process, free of charge, and it is often one of the first actions you’ll take after deciding on your business structure and completing registration. Even if you do not immediately plan to hire, obtaining an EIN early helps you keep personal and business finances cleanly separated—a prudent practice that reduces the risk of personal liability in financial matters and simplifies accounting as you grow.

With the internal framework in place, the external permission to operate arrives through the local licensing landscape. The local business license or permit you secure is the formal authorization that your city or county grants to operate within its borders. As with the other steps, the specifics vary widely from one place to another. Some jurisdictions bundle food truck permissions into a broader general business license, while others require a dedicated food-truck or mobile-vendor permit and possibly additional health or fire approvals. The path you follow will depend on where you park, how you prepare food, and what equipment you use. In practice, this means contacting your city or county government’s licensing office to understand the exact steps, fees, and timelines. There may be a requirement to submit a plan showing your truck’s layout, including the placement of cooking, refrigeration, and waste handling areas. Some places will also require background checks or proof of insurance as part of the licensing package. The complexity of this process is not a sign of a failing system but a reflection of the careful oversight needed to protect public health and consumer safety in a mobile dining environment.

Two additional dimensions shape this landscape and help you anticipate what comes next: health and safety compliance and the practical realities of operation. The health framework, while often outlined in separate permits, has to harmonize with your business structure and local licensing. A food service establishment permit or food facility permit is designed to ensure your truck meets sanitary and equipment standards. This typically means inspections of your vehicle, confirming that there is a logical flow from raw ingredients to finished products, that there are proper sanitation facilities, and that waste disposal is handled correctly. Your kitchen layout, ventilation, cold storage, handwashing stations, and the separation of raw and cooked foods all come under scrutiny. You may be asked to provide a diagram of your truck’s interior, illustrating the arrangement of cooking surfaces, prep areas, refrigeration, and waste containment. Health departments are vigilant about preventing cross-contamination and maintaining safe temperatures, and approvals here are foundational to the trust customers place in your brand.

Meanwhile, the broader regulatory environment requires that you stay abreast of food-safety training obligations for your team. A food handler’s permit or food safety certification often accompanies the licensing package, ensuring that all staff who work with food understand the basics of hygiene, safe handling, proper cooking temperatures, and personal cleanliness. Although the exact credentials vary by jurisdiction, the intent is consistent: to ensure that your crew follows best-practice procedures that minimize risk to the public. The combination of a robust structure, a registered business identity, an EIN, and a solid base of local licenses creates the infrastructure that makes your operation resilient in the face of audits, inspections, and evolving regulations.

It is natural to feel a moment of overwhelm, especially when you consider sweeping differences between cities. In practice, the approach becomes manageable when you view the timeline as a sequence rather than a single leap. Start with the structure and the DBA, then obtain the EIN, followed by the local license. As you move through these steps, you will also identify the required health permits, which may include a health inspection certificate when your truck meets the safety standards and passes review. In cities with a strong health-regulation culture, such as those with mobile-vendor programs, the process may begin with a Mobile Food Facility Permit. In other areas, the permit may be rolled into a general business license. For a practical, up-to-date perspective, consider the broader regulatory landscape that guides these decisions and how it applies to your location by exploring resources on the dedicated page for navigating food-truck industry regulations. This resource helps you understand not only the paperwork but the rationale behind it, which empowers you to prepare thoroughly and avoid costly rework.

The path is not merely procedural; it weaves through your business’s identity and daily operations. Naming, structure, and registration set a tone of professionalism that customers recognize, while the licensing and health approvals establish a predictable framework in which you can safely and reliably serve your community. When you combine these layers with a clear kindness to regulatory requirements and a well-planned sequence, you create a foundation that stands up to audits, seasonal fluctuations in demand, and the inevitable complexities that come with running a mobile kitchen. It is also worth noting that the perimeters of these requirements can shift with local policy changes, so a standing routine of annual checks with the licensing office—or your attorney or a compliance consultant—can save you later. The aim is not to chase compliance every week but to build a system that anticipates changes and stays aligned with ethical and legal obligations.

As you prepare to move from idea to rollout, you can leverage a practical mindset: map the steps to your city’s specific realities, build your internal infrastructure in parallel with external approvals, and keep the lines of communication with local authorities open. This approach minimizes delays, helps you budget accurately for licensing fees, and reduces the risk of retroactive changes that could disrupt a launch plan. A helpful way to frame this is to think of permits as a coordinated ecosystem rather than isolated hurdles. The structure you choose informs how you manage documentation; the DBA and registration connect to how you access bank accounts and insurance; the EIN ties into payroll and taxes; and the local licenses, health permits, and handler certifications collectively enable you to operate with legitimacy and accountability. When the pieces fit together, your food truck becomes not just a concept but a verified enterprise with a recognized footprint in your community.

For readers seeking a broader map of this landscape, a practical resource on regulations and the regulatory journey of mobile food operations can offer a step-by-step orientation and checklists that align with your location. And as you plan your next moves, remember that this is about building trust as much as about compliance. Your customers will feel more secure knowing the business behind the truck is properly registered, insured, and regulated, and your team will appreciate the clarity that comes from clearly defined roles, a transparent structure, and standardized procedures. With a solid legal backbone, you can focus more energy on menu creativity, service quality, and the vibrant experiences that define successful food-truck ventures.

Internal link for practical guidance: navigate the regulatory landscape through the resource on navigating food-truck industry regulations, which provides location-aware insights and realistic timelines for obtaining permits and approvals.

As you look ahead, the next chapter will build on this foundation by translating these legal and administrative steps into a tangible operating plan. You will learn how to align menu development, procurement, and kitchen design with the permits already secured, ensuring your truck is not only compliant but also efficient and scalable in a competitive market. The journey from business concept to bustling curbside business is paved with careful preparation, steady diligence, and a willingness to engage with the regulatory environment as a partner rather than an obstacle. For those seeking a broader framework beyond the city-level requirements, the Small Business Administration’s Start Your Business guide offers a comprehensive overview of starting and growing a legal enterprise, including considerations for taxes, licensing, and structure as you navigate the early stages of your venture: https://www.sba.gov/business-guide/plan-your-business/start-your-business

Permits on Wheels: Mastering Mobile Vendor Licenses and Local Approvals for Your Food Truck

The path from concept to the first day on the curb begins with permits, a framework that keeps the food you serve safe and your operation compliant. In the world of food trucks, permits are not just paperwork; they are the contract that binds your business to public health, local policy, and the community you serve. This chapter focuses on the sequence that many cities expect you to follow, with a practical emphasis on the central role of the Mobile Food Vendor license and the local approvals that come after. In cities like New York, this order is not merely recommended; it’s often the gate through which every other license must pass. Start here, and you reduce delays later when you move into route planning, event signups, and day-to-day operations that rely on clean, documented compliance.

The journey usually starts with securing a Mobile Food Vending license. In many jurisdictions, this license represents the city’s acknowledgment that you meet the basic requirements to operate a food truck on public streets. If you don’t already have it, apply for it first. In New York City, for example, you can find guidance and apply online at the official health department portal dedicated to mobile food vending. The process is web-based and public-facing, designed to guide hopeful operators through eligibility checks, documentation, and the submission steps. If you run into questions or need clarification on timing, a call to the city’s information line can connect you with the right office for mobile vending specifics. This license acts as a foundation; without it, many other permits cannot be pursued or approved.

Once the mobile vending license is in hand, the next critical step is the Food Service Establishment Permit, or its local equivalent. This permit is about health and safety in a more granular sense. It confirms that your vehicle and your operation meet the standards for sanitation, equipment, and workflow. The application requires careful preparation of several documents: a completed permit form, a copy of your individual business license or sole proprietorship registration, and proof of a designated operating location such as a lease, site plan, or approved route. A thoughtful layout diagram of the truck’s interior is essential. It should clearly show where cooking, refrigeration, and washing occur, where waste and wastewater are disposed of, and how the food flow moves from storage to service. You’ll also need to provide a list of all equipment used for food preparation and storage. The health authorities may also request a copy of your food safety management policies, which cover employee health checks, supplier and ingredient sourcing records, and procedures for addressing possible foodborne illness incidents. The emphasis here is not on cleverness but on clarity: inspectors need to see that your operation has defined, trackable, and enforceable systems.

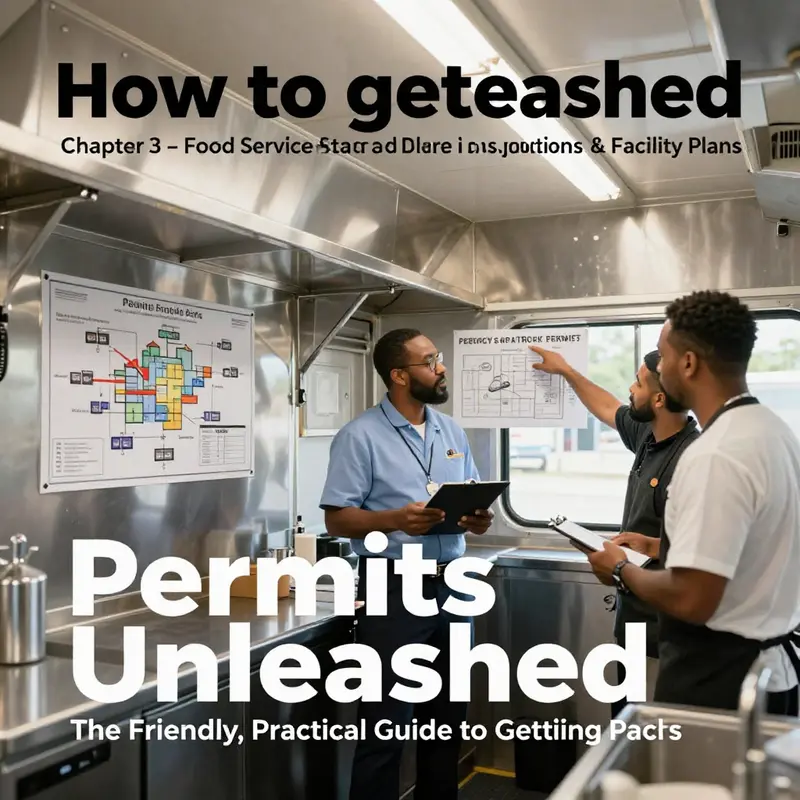

The approval for the Food Service Establishment Permit often prompts a formal inspection of the truck. A health inspector will verify that sanitation stations, ventilation, cold and hot holding, handwashing facilities, and waste disposal align with regulations. Preparation for this inspection is as important as the application itself. Having a well-drawn site plan and a precise layout diagram helps inspectors quickly compare what the plan shows with what they observe on the day of the visit. Expect questions about how you will clean equipment, how you record temperatures, and how you manage cross-contamination risks. A positive inspection yields the permit, but it can also reveal gaps that you must address before the permit is granted. The process is iterative by design; you may need to update layouts or adjust workflows to satisfy local standards.

Beyond the kitchen floor, several other permits contribute to a compliant operation. A Food Handler’s Permit or equivalent food safety certification is typically required for anyone who handles food. This is not a one-and-done credential; it represents a baseline understanding of safe handling, temperatures, hygiene, and contamination prevention that applies to every crew member. It ensures that the people who touch the ingredients and finish products have a common framework to minimize risk. In many places, the certification is obtained through state or local health departments, often via a sanctioned course or exam. Keeping up-to-date with these certificates is important, as some jurisdictions require renewals or periodic verifications when staff changes occur.

Another pillar is the Health Department Permit or Health Inspection Certificate. This is the practical measure that your truck has met ongoing health requirements and will be subject to periodic inspections. It’s not only about passing one initial audit; it also signals that your operation intends to maintain standards over time. Many operators underestimate how much this ongoing oversight shapes their daily routines. Sanitation schedules, cleaning logs, pest control plans, and routine calibration of equipment become daily habits because they are part of meeting the expectations of the permit. When a health department visits, you should be able to present clear records of temperature logs, supplier certificates, and evidence of routine maintenance—everything that shows you are operating reliably and safely.

In parallel with safety and sanitation responsibilities, consider a Sales Tax Permit if your jurisdiction requires charging and remitting sales tax on taxable food items. This permit, sometimes overlooked in the excitement of a new business, ensures you collect the right amount of tax and report it properly. Even if your jurisdiction does not levy sales tax on certain items at all times, understanding the rulebook and ensuring you’re prepared to meet tax obligations is part of professional practice.

The exact process and the documents you’ll need can vary considerably by state and municipality. The core idea, however, remains constant: begin with a mobile vending license, then secure a food service establishment permit, followed by the health inspection certificate, and finally the certifications for your staff and any tax registrations. The chain is only as strong as its weakest link, so you should approach each step with thorough preparation and a clear checklist. Local government offices, your state health and agriculture departments, and the business licensing office will be your ongoing resources. For the most accurate, up-to-date instructions tailored to your area, always consult your local health department or business licensing office. In practice, that means visiting the relevant city or county portal and, if available, using state resources as a cross-check for state-specific health or food safety requirements.

To connect the dots between permitting and everyday operations, build a practical documentation folder early in your planning. Gather copies of your individual business license, proof of a designated operating location, layout diagrams, equipment inventories, and copies of your food safety policies. Create digital backups and organize them by permit type so you can present the right set of documents when you apply. Expect that some documents will require updates as you respond to inspector feedback or as your operating plans evolve. A well-organized dossier not only speeds up the process; it also reduces back-and-forth with officials who value clarity and completeness.

As you navigate this landscape, a broader perspective on regulatory navigation can be helpful. For a more expansive treatment of how to interpret and manage the regulatory maze that food trucks face, consider our discussion on navigating food-truck industry regulations. It offers a wider lens on how cities structure permits, how to anticipate changes in policy, and how to align your business plans with evolving rules. navigating food-truck industry regulations.

Throughout this process, remember that every jurisdiction has its own nuances. While the NYC example provides concrete steps and a clear portal for guidance, other cities and counties may require additional documents or slightly different naming for permits. The safest path is to start with the official portal for your location, download the exact application forms, and read any guidance notes or checklists the agency provides. If you’re unsure, call the relevant department or visit in person to confirm the sequence and the required documentation. The aim is not to memorize a long list of lines but to cultivate a reliable workflow that can be scaled as you expand to more routes, more events, and more menus.

Finally, keep your eyes on the horizon. Permits aren’t a one-off hurdle but a recurring framework that supports your ability to operate, expand, and adapt. A well-documented, compliant operation makes it easier to secure permits for new locations, to participate in special events, and to demonstrate reliability to potential partners or sponsors. The better you understand the permit ecosystem, the faster you can turn ambitious ideas into consistent service, with the confidence that every plate you serve meets safety standards and every curb you park on is legally authorized. This integrated mindset—the blend of paperwork, practice, and ongoing compliance—will help you move smoothly from launch to expansion without the friction that comes from missing documents, failed inspections, or last-minute permit gaps. When you align your operation with local approvals from the outset, you’re not just following rules—you’re building a trusted, resilient business that can weather changes in policy, demand, and market conditions. And when the next permit cycle arrives, you’ll be ready to respond with the same clarity and preparedness that got you started in the first place. For the next step in this journey, we turn from permits to menu strategy and the logistics of setting your truck up for growth, all while staying within the bounds of the approvals you’ve already earned.

Blueprints in Motion: Mastering the Food Service Establishment Permit for a Mobile Kitchen

Every food truck begins with a single, practical reality: it must prove that its kitchen can be clean, safe, and compliant with local health rules before a single burrito is handed to a customer. The Food Service Establishment Permit is not merely a checkbox to tick; it is the hinge between ambition and operation. In many jurisdictions, this permit is the foundational credential that demonstrates your mobile kitchen has been designed with sanitation and public safety in mind. The process starts long before the first cooking flame flickers. You will be asked to submit detailed facility plans that lay out every inch of the truck’s interior—the places for refrigeration, cooking surfaces, handwashing, sinks for washing, rinsing, and sanitizing, as well as the areas where waste will be disposed of and cleaned. The diagrams are not decorative; they are a blueprint for safety. They show the placement of equipment in relation to workflows that minimize cross-contamination and ensure that temperatures stay within safe ranges throughout every step of food handling. In practical terms, the plan needs to convey that the truck can maintain proper separation between raw ingredients and ready-to-eat foods, that refrigeration units will perform reliably under daily shop traffic, and that wastewater and cleaning supplies will be stored away from food contact zones. The health department relies on these diagrams to assess whether your interior layout aligns with the health code, not just in theory but in the real rhythm of a busy service window. The level of detail demanded is substantial, typically requiring a layout diagram that shows the exact placement of the cooking line, refrigeration, handwashing facilities, sink arrangements, and waste disposal areas. This is not a generic kitchen sketch; it is a precise map of your operation’s safety infrastructure. You’ll often need to address how you will handle hot and cold storage, how you will prevent cross-contamination between raw and cooked products, and how you will maintain sanitation throughout service, including the means for effective cleaning and sanitizing of equipment between uses. The more thorough and accurate your facility plans, the smoother the review will be, because inspectors won’t have to imagine how your truck will operate under pressure—the plan shows them. Once these plans have been submitted, the health department assigns a critical next step: an on-site inspection. During this visit, a health inspector will walk through the truck, checking that everything on the plan exists in real life and that it functions correctly. They will verify that you have a reliable hot water supply for handwashing and cleaning, a working three-compartment sink or equivalent sanitation station, and properly sealed and maintained refrigeration units that can hold the required temperatures. They will also examine how waste is stored and removed, ensuring that condensation, spills, and refuse will not contaminate food preparation areas. The inspector will observe the flow of operations during a mock service to ensure that the actual work processes align with the safety protocols depicted in your plans. Above all, they will assess sanitation practices: whether there are clear lines of responsibility, whether cleaning schedules are posted and followed, and whether buffers and sanitizers are available in appropriate quantities and locations. If any element fails to meet the standard, the health department will note the deficiencies and request corrective actions. Depending on the jurisdiction, you may be required to implement changes on the spot or submit revised plans and a re-inspection after you have made the adjustments. The accountability is real, but so is the possibility of a successful outcome if you approach the process with both diligence and adaptability. The permission granted after a successful inspection signifies more than permission to operate. It is a formal acknowledgment that your interior is configured for safe food handling and that your staff can maintain that standard in a live, high-volume setting. In many places, this permit functions as a gatekeeper, a prerequisite that unlocks the door to additional licensing steps needed to operate legally. The chain of approvals can vary widely from one city or county to the next, and some locales even treat the Food Service Establishment Permit as the first major hurdle that a mobile food business must clear before any other licenses are pursued. That is why, when you begin assembling your plans, you should also take a broader view of the regulatory landscape. A thorough understanding of how your local jurisdiction structures its approvals will help you prepare more precisely, avoid duplicate submissions, and anticipate the timing of each milestone. To gather context beyond the plan and the on-site check, many operators also consult broader regulatory guidance that ties these local requirements to national food safety expectations. For instance, there is value in exploring general resources that discuss mobile food operation permits and inspections, as well as how these elements fit into the overall licensing ecosystem for a food truck. One practical path is to review the broader regulatory guidance linked in related resources, such as a comprehensive overview of food safety rules and permitting for mobile operations. This kind of guidance helps you connect the dots between the interior design you submit on paper and the daily practices you will carry out during service, ensuring that every step—from procurement and storage to cooking and serving—complies with health standards and protects public safety. As you align your facility plans with these expectations, you may also find it useful to look at other operators’ experiences and checklists for interior layouts and inspection readouts. A well-documented planning process reduces the risk of surprises at inspection time and gives you a concrete, auditable trail that demonstrates your commitment to safety and compliance as your business grows. For operators who want to go a step further in ensuring preparedness, the path from plan to permit is often smoother when you integrate practical considerations into the early design phase. A key aspect is to maintain a clear separation between the food preparation zone and any non-food areas, such as vehicle mechanical spaces or storage for non-food supplies. The trend in many jurisdictions is to favor layouts that minimize cross-contact possibilities and make cleaning more straightforward, which, in turn, supports faster pass rates during inspections and quicker licensure. If you are considering collaborations or shared commissary space, factor in how the facility plan translates to that environment as well. The plan must reflect the realities of shared spaces, where water access, waste handling, and cold storage are coordinated across multiple tenants. This can require additional documentation or a narrative explanation within your submission to reassure inspectors that your operation will remain compliant regardless of fluctuations in the surrounding workflow. In the end, the drumbeat of successful permitting comes from turning a well-thought-out design into verifiable practice. Your facility plans serve as your proof of concept, your on-site inspection guide, and your operational blueprint rolled into one. They capture not only where things go, but how they are managed to keep customers safe and food costs under control during a busy service window. The permit, once granted, is not a final certificate but a foundation upon which your ongoing compliance rests. It signals to customers and regulators alike that your truck is more than a mobile kitchen; it is a certified, safety-conscious micro-restaurant on wheels. For broader regulatory guidance and additional context on how mobile operations fit into the larger framework of food safety, you can refer to the resource on navigating food truck regulations. Navigating Food Truck Industry Regulations. Finally, while the specifics of each jurisdiction will differ, everyone pursuing a Food Service Establishment Permit should plan for a structured sequence: plan submission, plan review, on-site inspection, corrective actions if needed, and final permit issuance. This sequence, followed with attention to detail, elevates the chances of a smooth approval process and sets the stage for a successful, compliant food truck operation. For readers seeking deeper regulatory grounding, the federal food safety landscape offers extensive resources to complement local guidance, such as the FDA’s detailed materials on food safety and mobile operations. External resource: https://www.fda.gov/food

Safe Hands on a Moving Kitchen: Mastering Food Handler Certification and Employee Hygiene for Your Food Truck

Obtaining a food truck permit is a multi-layered process, and among the first and most important pieces is ensuring every person who touches food is properly trained and hygienic. This chapter weaves together the core requirements of Food Handler Certification and the badges of personal and procedural hygiene that health departments insist upon. It shows how certification isn’t just a box to check; it is the foundation of trust with customers, a practical safeguard for safety, and a concrete signal that your operation is prepared to serve meals that meet consistent standards wherever your wheels take you. In many jurisdictions, you will discover that while the specific licenses you need vary, the certainty you gain from a well-trained team remains universal: proper knowledge, disciplined practice, and visible adherence to health regulations underpin every permit, every inspection, and every positive customer interaction.

At its core, a Food Handler Certification confirms that an individual has completed a recognized training program covering essential food safety principles. The curriculum usually spans safe storage, preventing cross-contamination, controlling temperatures, and maintaining personal hygiene. It is not enough to memorize rules for a single day; the certificate represents a baseline competence that you rely on every service window, every event, and every shift change. In many places, certification is mandatory for anyone who handles food, whether you are the owner-operator, a cook, or a prep person. The typical renewal cycle is every three years, though some states or cities may require more frequent refreshers until you demonstrate continued compliance. This cadence matters for planning your staff onboarding and ongoing training budgets, because a lapse in certification can stall operations or complicate inspections.

What your team needs, then, is not just a certificate but a robust program that keeps the knowledge current and the execution consistent. Accredited providers—such as widely recognized programs run by national associations, state or local health departments, or state-approved online providers—offer structured pathways to certification. You’ll want to confirm the list of approved providers for your jurisdiction and align your timeline so that every person who handles food is certified before their first shift. The practical implication is straightforward: you plan for training, you schedule the exams, and you maintain a clear record that is readily available for inspection if questioned. The process rarely stands alone. It dovetails with your broader compliance framework, which includes equipment readiness, sanitation plans, and the workflows you design inside the truck.

Designing that workflow begins with recognizing how the mobile kitchen environment shapes hygiene practices. A food truck imposes space constraints that make certain hygiene features both more critical and more challenging. You should have a designated handwashing area with a continuous supply of running water, a reliable soap dispenser, and single-use towels. A separate basin for washing equipment, a clean storage area for sanitized tools, and clearly labeled waste disposal zones help prevent cross-contamination by design, not by hope. When a crew member finishes handling raw poultry, for example, there should be a fast and simple path to wash hands and, if needed, to change gloves. Your training program must mirror this reality. It should include demonstrations and checklists that can be used during busy service periods, reminding staff to wash hands after touching the service counter, after removing gloves, and after using the restroom.

A core principle of certification training is understanding temperature control. Food safety hinges on keeping cold foods cold and hot foods hot, with a clear understanding of the danger zone and safe holding times. Because a truck’s refrigeration, warming equipment, and even ice storage can vary from one setup to another, your team must learn how to monitor temperatures using calibrated thermometers, how to log readings when required, and how to respond if a thermometer reads outside safe ranges. This is not merely a compliance exercise; it’s a practical habit that reduces the risk of pathogen growth and preserves flavor and texture. In addition, proper storage practices—including organizing raw ingredients separately from ready-to-eat items and ensuring that all perishables are properly labeled with dates—become part of standard operating procedures that your crew can execute consistently during service.

The personal hygiene part of the certification extends beyond the obvious to the habits thatcustomers may not notice but that health inspectors will scrutinize. Clean uniforms, hair restraints, and the avoidance of jewelry that might harbor microbes or snag equipment all matter. The expectation extends to how staff interact with customers and how they manage the space around the service window. A comprehensive hygiene plan includes handwashing technique education, with a focus on the difference between a quick rinse and a thorough scrub, as well as the appropriate times for washing hands—before starting work, after breaks, after using the restroom, after touching raw ingredients, and after touching money. Some inspectors also check whether there are systems in place for illness reporting and substitution coverage, which is essential to avoid sending an unwell employee into food preparation areas.

Because a food truck moves between locations, the certification’s value compounds when paired with visible hygiene signals. Fresh hair restraints, clean aprons, and glove use when handling ready-to-eat foods all serve as visible assurances to customers that you are taking precautions seriously. Documentation is equally important. Your operation should maintain records of who is certified, the expiration dates, and the training dates for any refreshers. When a health department inspector arrives, these records become a narrative of your ongoing commitment rather than a momentary snapshot. A well-managed set of records can also help you anticipate renewal needs and allocate budget for ongoing training and compliance activities, ensuring you don’t find yourself scrambling to replace an expired certificate during a busy service period.

The penalties for falling short on certification and hygiene are concrete and meaningful. Fines, temporary closures, or even revocation of your operating permit can follow if a health department determines that your team lacks proper certification or repeatedly fails to meet hygiene standards. The consequences extend beyond the legal or financial. Food safety incidents erode customer trust and can quickly tarnish a brand’s reputation, especially in a mobile business that relies on repeat visits and social sharing. The upside of adherence is equally tangible: smoother inspections, fewer service interruptions, and a reputational edge that resonates with customers who value safety as much as taste.

To navigate the specifics of your area, a practical approach is to anchor your planning in the local health department’s guidance while using national frameworks as a sanity check. The FDA’s food safety education resources provide a broad baseline that can help you interpret local rules and communicate best practices to your team. While these are general standards, they reinforce the logic of why certain steps exist and how your operation should function on a daily basis. Of course, the exact course and renewal requirements will come from your state or municipal health department, so your next step is to map out a concrete plan: identify the approved certification providers, schedule upcoming trainings for all current staff, and set reminders for renewal well in advance of expiration dates.

A useful way to keep this process integrated with your broader permitting effort is to view certification as a living component of your business system. Build a simple onboarding pathway for new hires that includes immediate certification steps, a hands-on hygiene orientation, and a buddy system to reinforce correct practices during the first weeks of operation. Create a one-page hygiene checklist that front-line staff can consult during shifts, and pair it with a digital or paper log for handwashing and temperature checks. These tools are not mere paperwork; they are the practical heartbeat of a compliant kitchen on wheels. When your truck earns its health department permits, you will be drawing on a familiar, tested set of practices rather than improvising under pressure.

As you plan for growth, remember that the certification and hygiene program you implement today will support your longer-term ambitions. A strong compliance culture reduces risk during peak service periods and at large events where the volume of guests spikes and the potential for cross-contamination increases. It also positions you as a responsible operator in discussions with event organizers, landlords, and local regulators, who prefer vendors who demonstrate a consistent, transparent commitment to food safety. In short, Food Handler Certification is not just a credential; it is a practical framework that informs how you train, how you operate, and how you communicate your standards to customers and partners alike.

For those seeking broader context on how these programs fit into the wider food-safety ecosystem, resources from reputable authorities can provide helpful background. The FDA’s food safety education materials offer foundational insights into the science behind safe handling and the reasons behind specific practices. While your local health department will dictate the exact certifications and renewal cycles you must observe, aligning your internal practices with these broader guidelines helps ensure you stay current and prepared for the evolving standards of mobile food service. If you want to explore these general principles further, you can refer to the FDA’s education resources and related guidance as a baseline reference.

To keep you oriented within the broader landscape of the mobile-food industry and to connect your certification journey with practical, real-world considerations, consider exploring related discussions on industry regulations and operational readiness. A useful entry point is navigating food-truck industry regulations, which outlines how jurisdictions assess and enforce requirements for mobile food businesses. This resource helps you anticipate potential changes in rules as you expand or relocate and reinforces the idea that a proactive, organized approach to compliance is your best ally in building a durable, compliant food truck operation.

In summary, Food Handler Certification and employee hygiene compliance are not standalone hurdles but a unified discipline that informs every shift and every interaction with the public. Your staff’s knowledge, the visibility of hygiene practices, and the accuracy of your records collectively shape your ability to obtain and maintain the permits that let your truck roll. When you integrate certification training, consistent hygiene routines, and clear documentation into a cohesive system, you reduce risk, protect customers, and foster the trust that turns first-time visitors into repeat customers. As you prepare for inspections and negotiate permits, this approach becomes your operational backbone, ensuring that your food truck not only meets the letter of the law but also embodies the spirit of safety and excellence that customers expect from a mobile kitchen.

External resource: For broader context on food safety education, consult the FDA’s consumer education resources: https://www.fda.gov/food/fda-food-safety-education

Cleared for the Road: Health Inspections, Taxes, and Ongoing Compliance for Your Food Truck

Cleared for the Road begins, almost paradoxically, with keeping faith with the public you serve. After you have established a business, registered a vehicle, and secured the basic mobile vendor permissions, the next gate is not a single entry but an ongoing discipline. Health inspections, sales tax compliance, and the routines that keep you in good standing form a continuous loop that protects customers, supports your reputation, and guards your operation against costly mistakes. The exact requirements will vary by city, county, and state, yet the core logic remains consistent: prove that you manage food safety, collect and remit the right taxes, and sustain a system that makes continuous compliance doable, not punitive. To ground this journey in practical terms, imagine stepping into the health department as a partner rather than an adversary, with a floor plan in hand, a clean kitchen on wheels, and a schedule that anticipates every renewal and review. In many jurisdictions, the health inspection is the formal stamp that your food handling and your unit can be trusted to operate day in and day out. You will be asked to demonstrate that your truck is designed for safe food production and storage. You will show that surfaces are cleanable, that equipment works as specified, and that the flow of food from storage to service minimizes cross contamination. The emphasis is on control and clarity. There is a reason behind the requirement for a floor plan detailing where cooking happens, where cold and hot foods are stored, where waste goes, and where handwashing occurs. A well-thought layout is more than a drawing; it is a living assurance that the truck can be cleaned thoroughly and sanitized regularly, that wastewater is managed properly, and that food safety can be maintained during every shift, even during a busy line at a market or festival. The inspection will also consider how your truck is powered, how it receives water, and how it handles ventilation and pest control. Jurisdictions often require that the vehicle be inspected for proper ventilation, safe electrical work, and the ability to meet temperature control standards. In short, the inspector is testing the backbone of your operation: the systems that keep food safe from prep to plate. Preparing for this moment means more than a once-a-year sweep of supplies. It means creating a routine culture of cleanliness and accountability. Your team should have documented procedures for cleaning and sanitizing all contact surfaces, for calibrating thermometers, and for recording temperatures of both hot and cold holding units. It is common to be asked to provide temperature charts covering a typical day, confirming that perishable foods never dip into unsafe ranges. A single misplaced logbook entry can prompt a recheck, so durable recordkeeping matters as much as the actual practice. The reality is that most inspections hinge on habits. A clean truck is not a cosmetic gesture but a sign that the operators understand the daily rituals of safe food handling. Staff training flows from this premise. Every employee who handles food must have a valid food handler permit or certificate. This demonstrates a basic grasp of cross-contamination risks, time-temperature control, and personal hygiene. The aim is not to test memorized rules but to ensure a minimum, consistent standard is met across the team. And because mistakes happen, you want a culture that makes it easy to correct them, to document corrections, and to prevent recurrences. When the day of inspection arrives, gather the items that validate your kitchen practices. Bring your business license, your proof of insurance, your vehicle documentation, and your floor plan. Having a ready list and a conversational tone with the inspector can ease tension and speed the process. If you keep a running inventory of equipment lists and supplier records, you will also demonstrate that you can trace ingredients back to source, a core liability control in today’s food safety environment. The inspector may walk through your truck, take notes, and request specific evidence of compliance, such as a cleaning schedule or a pest-control contract. They may pose questions about sourcing and preparation, so you should be prepared to explain how you prevent cross-contact and how you manage special dietary considerations. If a deficiency arises, do not fear it. Most authorities provide a pathway to remedy through a formal correction plan and a reinspection window. The key is responsiveness: address the issue promptly, document the fixes, and reschedule the follow-up with transparency. This approach reframes the experience from a hurdle to a constructive step toward more robust operations. After you secure the health permit, ongoing compliance becomes the rhythm of daily business rather than a distant milestone. Regular self-inspections, perhaps monthly or quarterly depending on local rules, help you stay ahead of violations. Temperature logs for both storage and cooking, cleaning schedules for each station, and a log of supplier deliveries are not bureaucratic chores; they are the backbone of operational reliability and customer trust. When you document and review these records, you create a narrative of care that you can share with customers and event organizers, underscoring your commitment to safety and quality. The next thread in the compliance tapestry concerns sales tax, a distinct but equally critical obligation. The path typically runs through the state revenue department, often via an online portal where you register for a sales tax permit. In most places you will receive a permit or resale certificate that enables you to collect the appropriate tax on food and beverages. The practical impact is that you must compute the correct rate at the point of sale, maintain clear records of taxable transactions, and file periodic tax returns, whether monthly or quarterly, depending on your jurisdiction. The operational implication is not simply about collecting tax; it is about integrating tax reporting into your daily sales flow. If you fail to collect accurately or to remit on time, penalties accumulate, and the reputation of your business can suffer alongside the financial consequences. A well-designed point-of-sale system can simplify this process by automating tax calculations and generating the transaction reports you need for filing. In tandem with these tax obligations, you will often hold a mobile vendor license or permit that is separate from the general business license. This permit may require proof of insurance, evidence of vehicle inspection, and sometimes site-specific scheduling or booking commitments. The exact configuration can differ widely, but the principle remains stable: operating in a constrained, permitted space with clear rules about where and when you can serve. The aim is to avoid the unpredictability of operating in a regulatory gray area where a single site decision could affect your entire schedule. Once these permits are secured, the focus shifts to ongoing practice. The combination of health, tax, and vendor oversight creates a living system in which permissions are renewed, conditions are verified, and operators stay current with training and documentation. The yearly renewals, periodic inspections, and updated certifications demand a reliable calendar and disciplined project management. A practical step is to build a compliance calendar that marks renewal dates, training expirations, and inspection windows. This calendar becomes a singular reference that anchors all compliance tasks, enabling you to plan ahead rather than react to deadlines. It is common to pair this with a standard operating procedure for food safety, cleaning, and recordkeeping that your entire crew can follow. When new staff join, the SOP is the first training material, ensuring a consistent baseline of safety. If you operate in multiple jurisdictions, the complexity grows, but the logic does not change. Each location maintains its own set of health and tax rules, yet your discipline—clear documentation, proactive renewal, and timely communication with regulators—remains the common thread across all sites. In this way, compliance becomes a competitive advantage. Customers learn that you take safety seriously, events prosper because your operations are steady, and you can participate in more opportunities with far less friction than a less organized competitor might encounter. For readers seeking a broader, cross-border perspective, there are programs and guidelines designed to illustrate how cities structure mobile food operations, including booking, inspections, and oversight. To ground your planning in a practical reference, consider the following external resource that outlines a mobile vendor pilot approach, including scheduling and fees: https://www.canning.gov.sg/hillview-precinct-mobile-vendor-pilot-guidelines. If you want a broader sense of how to navigate regulatory landscapes in your own area, you can also consult a resource focused on navigating food truck industry regulations. For ease of access, here is a relevant internal link that aligns with this chapter’s focus on the regulatory framework: Navigating food-truck industry regulations. As you advance, your aim is not to chase the perfect rulebook but to build a resilient practice that keeps you compliant, competitive, and trusted by customers who count on you for safe, dependable food on wheels.

Final thoughts

Permits aren’t obstacles to great food service; they are the rulebook that protects guests, staff, and your brand while giving you a scalable framework for growth. By treating licensing as a strategic phase—starting with a solid business structure, then securing the right mobile-vendor approvals, and finally aligning your kitchen design, staff training, and ongoing compliance—you build a foundation that can support multiple events, partnerships, and long-term success. Each chapter connects with the next: a strong legal identity makes licensing smoother; clear approvals enable daily operations; a compliant kitchen design reduces inspection friction; a trained crew delivers safety and consistency; and a culture of ongoing compliance sustains trust with clients, venues, and communities. As you embark or expand your mobile dining venture, remember that permits are not a roadblock but a roadmap—one that reveals the best paths to memorable experiences for event planners, HR teams, community groups, and food enthusiasts alike.